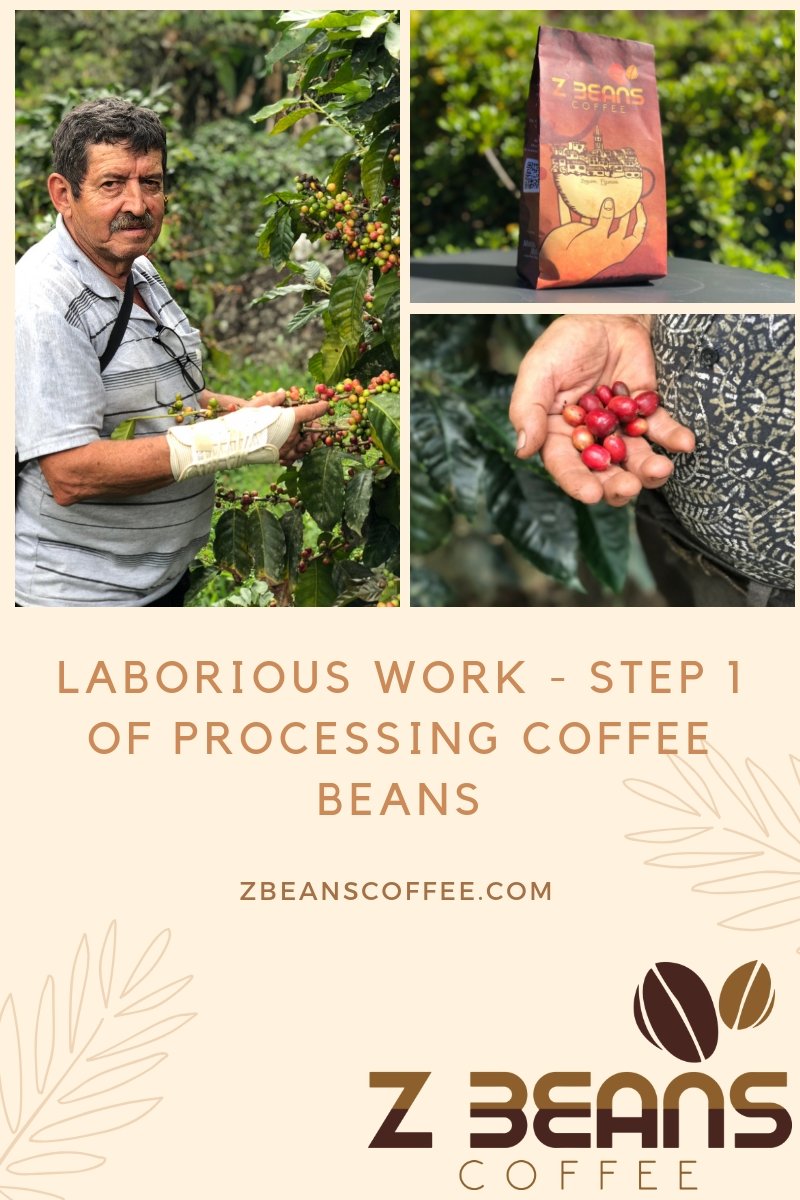

Laborious Work - Step 1 of Processing Coffee Beans

Laborious Work - Step 1 of Processing Coffee Beans

While we are always looking for the most efficient, productive ways to build our businesses or professional lives, crops do not respond well to this same type of attitude. No matter the crop, mass, streamlined production, in some way, sacrifices quality.

Do the tomatoes out of your friend's small garden always taste better?

...

The same holds true for a coffee plant.

We have seen this, first hand, in Ecuador. Because the farms are small and intermixed with other crops, the resulting canopy over top of the coffee plants creates shade. This shade prompts a slow, steady maturation process, eventually creating a superior coffee bean.

While many other factors play into a coffee plant's quality, as discussed in this article, quality control, in regards to agriculture, will always be more efficient on a smaller scale.

But, where is that line drawn?

This article discusses, in thorough detail, the first stage of processing coffee. Here, we will discuss the process from coffee cherry to dried husk. This process is told through the point of view of a hard working Ecuadorian.

...

It's 6:00 in the morning, and the sun is rising. I take my first step out the door. 5 miles up the road, the coffee plantation of Milton Rivadeneira waits for me. After a little over an hour of walking, I arrive. Milton hands me an empty sack and a bucket with a rope attached. I put the rope around my neck. The bucket hangs in front of me.

I head over to the edge of the plantation, gazing over the field. Where did I leave off yesterday? That's it. I find my spot and walk over.

I begin picking. One by one, I find the ripest coffee cherries. I place each one in the bucket. After 30 minutes, I've filled up my one gallon bucket. I dump them in the sack. After 4 and a half hours, I decide to take a break. One sack is full, and it's time for lunch.

I walk back up to the plantation. I chat with my friends as they finish up their work at the drying station. They are taking yesterday's thoroughly washed coffee husks and scattering them out on the table. After scattering, they rapidly pick out the defected beans and toss them in a bucket. Once they finish, we walk into the small cafeteria for lunch. The plantation owners will provide you with lunch if you would like for them to. They just take a small portion out of your pay at the end of the week.

Thirty minutes later, lunch ends. I grab another empty sack and head back out to work. I've already picked over 50 coffee plants - it's prime harvesting season, so we won't have too many more days of this.

4 hours in, I've finished my second sack. I'm tired, and it's about time to weigh-in anyways. So, I call for the truck. I walk both of my bags up to the closest dirt road and wait there. Shortly thereafter, the truck arrives. I toss my bags in the back and jump in.

Finally, the day has come to a close. We all sit in the back of the truck, look at each other's work for the day, and head back to the plantation.

When we arrive, some of the younger men are waiting on us. They get our bags out of the truck and walk them over to the scales.

There, Milton is waiting on us. We put each of our bags on the scale, and Milton writes down our weight. Milton actually pays us based on how many coffee cherries we pick.

After weigh-in, we toss our cherries in the big washing tub. Here, we fill up the tub with water, soak the cherries, then run the cherries through the pulp removing machine. The pulp remover creates a pile of coffee cherries, which we use as fertilization, and a pile of husks. The husks are transferred to a second tub where they are washed thoroughly. My friends remove the viscous substance from the husk, then lay them out on drying tables. The coffee husks will remain on drying tables for multiple weeks. Once the husks reach 15% humidity, they are moved to another drying table where they dry until they reach 11% humidity. Once they reach 11%, they are bagged up and stored, waiting to be sold.

Once the tub is filled with water, I can head back home. Thankfully, Milton doesn't make us all walk, though. He takes us all in his truck and drops us off - It sure makes a hard day's work a little sweeter.

At 6:00, I get back home. I thank Milton for the ride and tell him that I'll see him tomorrow!

0 comentarios